I had a bright idea for printing on the conveyor belts. I got some black vinyl to cover them up with. That way, I could print my images on the vinyl, and if anything went wrong (as things often do with screen printing) I could easily peel off the vinyl and do it again.

Sounds easy.

It wasn't.

Two nightmarish weeks of experimentation ensued, and they were definitely not worth the trouble.

Nope, nope, and nope.

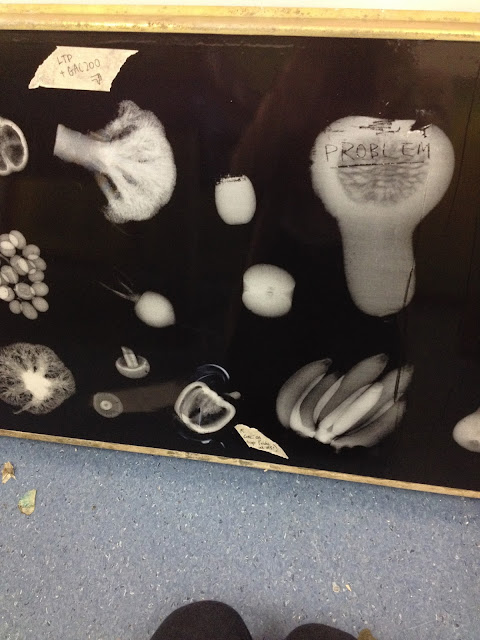

Above: CCG inks and Gac 200. This worked OK, it still rubbed off when scratched with enough pressure.

Using Live to Print plant based inks and Gac 200 in an attempt to make them more adhesive to the shiny surface... No such luck. Even when fully dry it did not stick to the surface at all and flaked off with the lightest touch.

50/50 gac to ink ratio, and still it rubbed off with the brush of a finger.

I had the best of intentions to use Live to Print inks, because they are so nice and matte in contrast with the shiny vinyl surface. I even emailed Matthew Lewis, the maker and supplier of these eco-friendly inks, to ask if he had any ideas for how I could make this work. Basically, his reply was that it's never going to work. The Live to Print inks are made for paper. For printing on plastic, you need another type of ink entirely, and no matter how much medium you add plant-based inks won't ever cut the mustard. In the meantime I'd been busily googling solutions, and this website reconfirmed that it was just never going to happen.

Then, deciding that the 'temporary' plastic surface wasn't worth the trouble, I removed the vinyl. Or, I tried to. It resisted coming off, and when it did, it came off in small strips and left a film of extraordinary sticky adhesive. It took six hours of peeling, scrubbing and half a bottle of rubbing alcohol before the surface was back to its original state.

I'm just so glad I used this as an experiment and didn't have to go through the same process with the other four belts, too.

Anyway, now I'm trying to work out a way of removing the roller from the back of the conveyor, because without that bar of steel pressing against the print surface, I won't need to worry quite so much about the durability of the ink. It's just a matter of whether it will still rotate without this tightness. The question then is what can be done about the metal brackets I've made to prop out the base from the wall - without the roller bar, the belt is slack, and rubs against these.

The adventure continues.